Product Categories

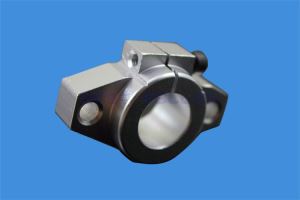

1, final cleaning before Assembly must use petrol to ensure all parts clean and dry to ensure the close conformity between the mating surfaces and no oil pollution, there is enough friction.

2, assembly using hex bolt Assembly wash and dry before using gasoline, do not paint oil or grease in the bolt or screw holes, to ensure that the bolt had enough the friction locking ability.

3, three Hexagon bolts to be installed when required turn fastening to ensure the sleeve by uniform axial force, ensure the pulley and the sleeve with the axes position is good.

4, the installation of check measurements before assembly using hex bolt length to ensure the Assembly bolt can resist blind hole sleeve bottom, cone close to ensure and guarantee bolt blind hole bottom of reverse thrust, principle of double nut locking function.

5, belt fastened after cable check and adjustment of main and driven pulley location ensured that the two wheels are in the same plane and belt tension properly.

6, pulley cover shall be in good condition and securely to ensure the running belt broken or loose pulley exit resulting in a serious accident.

7, sleeve belongs to the wearing parts, after a long period of operation, and then chain of hole and slot may be damaged and should be checked before each Assembly, found the defect should be timely replacement of spare parts.

Previous: experience on pulleys